ClearFox® Clarifier

Lamella Clarifier

Advanced Separation Process Technology

- Compact Footprint

- Various Configurations

- Modular

- Simple Operation

Gallery

Description

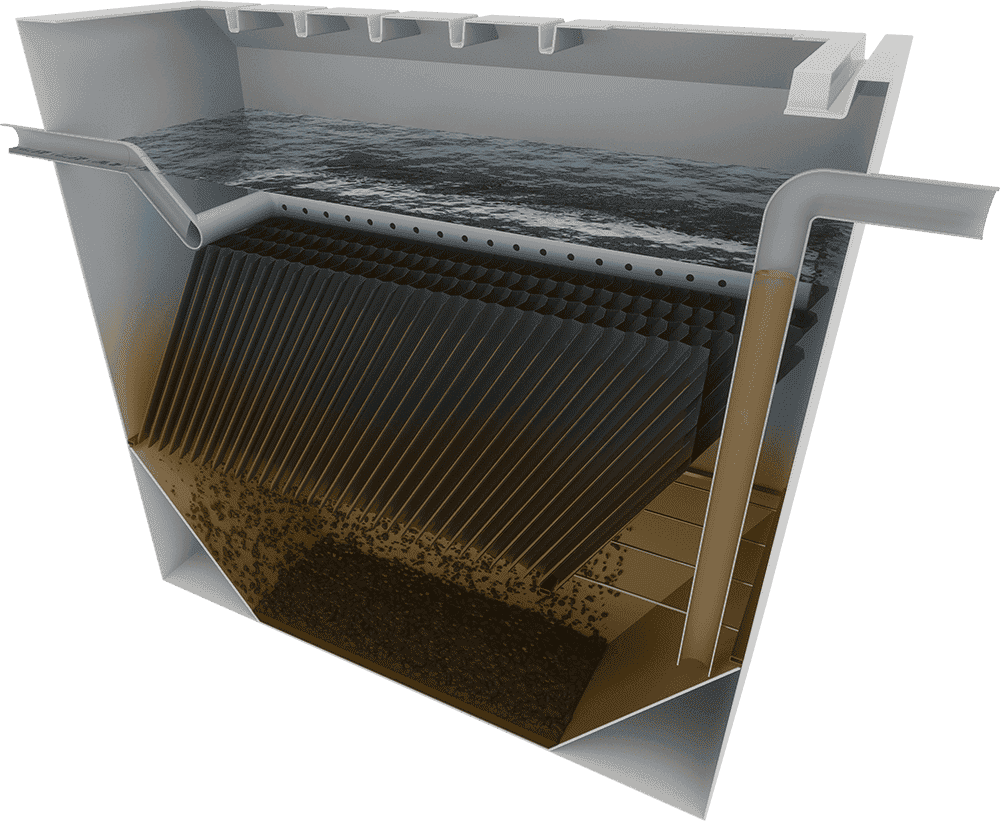

The ClearFox® Lamella Clarifier reliably separates settleable solids from process water and wastewater. The technology is based on the principle of sedimentation, which is significantly enhanced through the use of an inclined lamella plates. It is suitable for both industrial and municipal wastewater and can be flexibly used in both primary and secondary clarification stages.

How It Works

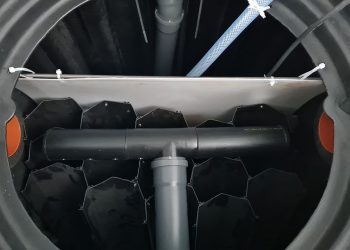

- Raw wastewater enters the upper section of the unit through the inlet channel and is directed downward (1)

- From there, the flow is redirected and moves evenly upward through the inclined lamella package (2)

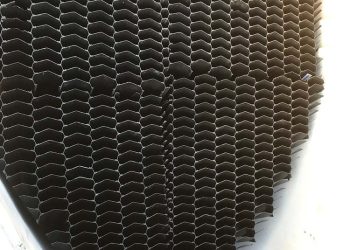

- The lamella modules are tilted at a 60° angle, creating optimal conditions for sedimentation. As the water slowly rises, sludge settles on the inclined surfaces. The settled solids slide downward in counterflow along the lamellae and are collected at the bottom of the tank in a sludge hopper (3)

- The sludge is then removed at regular intervals via a pump. Above the lamellae, the clarified water accumulates (4) and flows through an overflow weir to the system outlet (5)

Inlet Channel

Inclined Lamella Package

Sludge Hopper

Clarified Water

Outlet

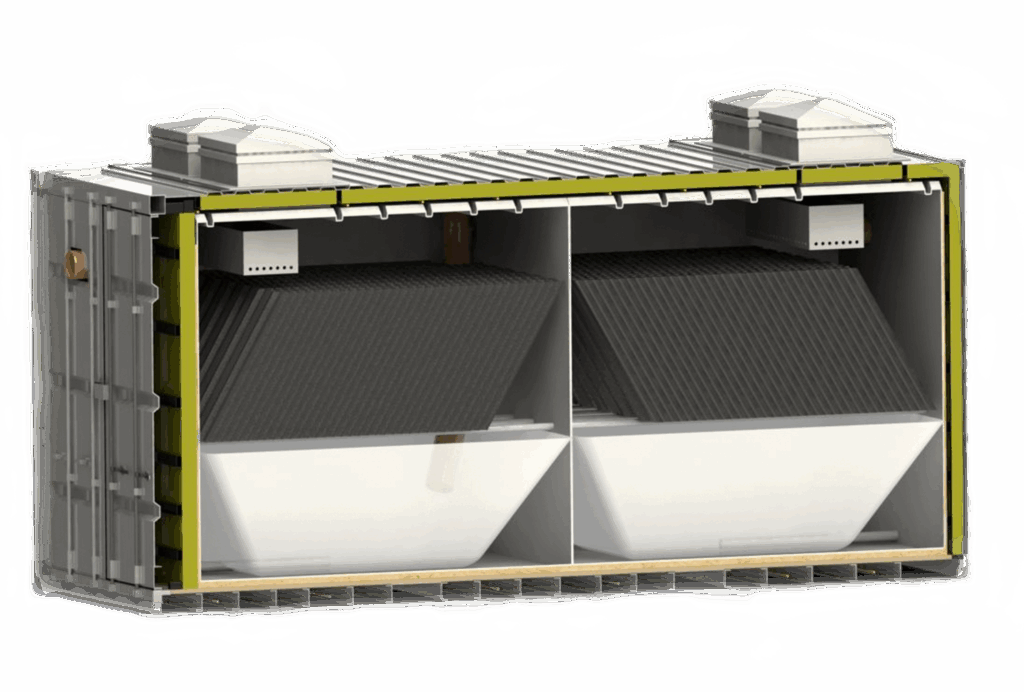

The technology is based on the principle of sedimentation, which is significantly enhanced through the use of an inclined lamella package. To effectively settle even smaller particles (smaller 50 μm), optional flocculants can be added. These produce larger, settleable flocs that are also then removed through sedimentation. The ClearFox® lamella clarifier is available as a ready-to-connect container solution, for underground installation in HDPE tanks, or in concrete structures. Each system is custom-designed and manufactured to meet your specific requirements.

Advantages

- Space Saving

Thanks to the inclined lamella modules, the effective settling area is significantly increased compared to conventional settling tanks, while the required space is reduced. In practice, the ClearFox® lamella clarifier requires up to 90% less space than traditional sedimentation systems. The compact design makes it especially suitable for locations with limited space and allows for easy integration into existing systems.

- Low Operating Costs

Our lamella clarifier operates without any moving parts and needs almost no energy. The lamellae are made of polyethylene, making them extremely durable and resistant to all wastewaters. For operators, this translates to minimal operational and maintenance costs and a consistently trouble-free system.

- Fast Turnaround

For standard sizes, the clarifier is delivered as a ready-to-connect system and is immediately operational. This enables quick integration into both new and existing facilities. Time-consuming assembly work is eliminated, significantly reducing installation costs.

- Flexible Design

The ClearFox® lamella clarifier is suitable for a wide range of applications. It can be used in both municipal treatment plants and industrial processes without any issues. Thanks to the containerized design, the system can easily be expanded as needed in the future. We offer containerized lamella clarifieres in various sizes. Freestanding, below ground, in PE tanks or in concrete tanks: We develop a solution tailored to your specific project.

Specifications

| Module | CL 2250 | CL 3500 | 20 ft. Container | 40 ft. Container |

|---|---|---|---|---|

| Max. Flowrate | 2,5 m³/h | 5 m³/h | 50 m³/h | 100 m³/h |

| max. transport weight: | 190 kg | 250 kg | 5.500 kg | 11.000 kg |

| Max. operating weight: | 2.300 kg | 3.550 kg | 30.000 kg | 60.000 kg |

| Inlet | DN100 | DN100 | DN100 | DN100 |

| Outlet | DN100 | DN100 | DN100 | DN100 |

| Dimensions: (l, w, h) (m) / (without steel frame) | 1,7/1,38/1,71 (1,54/1,22/1,71) | 2,59/1,38/1,71 (2,43/1,22/1,71) | 6,10/2,50/2,90 | 12,20/2,50/2,90 |

| Module | CL 2250 | CL 3500 | 20 ft. Container | 40 ft. Container |

|---|---|---|---|---|

| Max. Flowrate | 2,5 m³/h | 5 m³/h | 50 m³/h | 100 m³/h |

| max. transport weight: | 190 kg | 250 kg | 5.500 kg | 11.000 kg |

| Max. operating weight: | 2.300 kg | 3.550 kg | 30.000 kg | 60.000 kg |

| Inlet | DN100 | DN100 | DN100 | DN100 |

| Outlet | DN100 | DN100 | DN100 | DN100 |

| Dimensions: (l, w, h) (m) / (without steel frame) | 1,7/1,38/1,71 (1,54/1,22/1,71) | 2,59/1,38/1,71 (2,43/1,22/1,71) | 6,10/2,50/2,90 | 12,20/2,50/2,90 |

| Module | CL 2250 | CL 3500 | 20 ft. Container | 40 ft. Container |

|---|---|---|---|---|

| Max. Flowrate | 2,5 m³/h | 5 m³/h | 50 m³/h | 100 m³/h |

| max. transport weight: | 190 kg | 250 kg | 5.500 kg | 11.000 kg |

| Max. operating weight: | 2.300 kg | 3.550 kg | 30.000 kg | 60.000 kg |

| Inlet | DN100 | DN100 | DN100 | DN100 |

| Outlet | DN100 | DN100 | DN100 | DN100 |

| Dimensions: (l, w, h) (m) / (without steel frame) | 1,7/1,38/1,71 (1,54/1,22/1,71) | 2,59/1,38/1,71 (2,43/1,22/1,71) | 6,10/2,50/2,90 | 12,20/2,50/2,90 |

| Module | CL 2250 | CL 3500 | 20 ft. Container | 40 ft. Container |

|---|---|---|---|---|

| Max. Flowrate | 2,5 m³/h | 5 m³/h | 50 m³/h | 100 m³/h |

| max. transport weight: | 190 kg | 250 kg | 5.500 kg | 11.000 kg |

| Max. operating weight: | 2.300 kg | 3.550 kg | 30.000 kg | 60.000 kg |

| Inlet | DN100 | DN100 | DN100 | DN100 |

| Outlet | DN100 | DN100 | DN100 | DN100 |

| Dimensions: (l, w, h) (m) / (without steel frame) | 1,7/1,38/1,71 (1,54/1,22/1,71) | 2,59/1,38/1,71 (2,43/1,22/1,71) | 6,10/2,50/2,90 | 12,20/2,50/2,90 |

Downloads

Reference Projects

FAQs

1. What is a ClearFox® Lamella Clarifier?

A ClearFox® Lamella Clarifier is a primary clarification device designed to remove solid particles from liquids, effectively managing raw wastewater with high concentrations of suspended solids. It utilizes inclined plates (lamellas) to enhance the settling process, requiring up to 80% less space compared to traditional settling tanks.

2. How does a Lamella Clarifier work?

Wastewater enters the clarifier through the inlet channel at the top and flows to the bottom of the separator. As it flows upward through the inclined lamellas, solid particles settle onto these plates. The treated water continues to the top, reaching the outlet by passing over a weir. Settled solids (sludge) slide down the lamellas and are collected in a sludge funnel for periodic removal.

3. What are the advantages of using a ClearFox® Lamella Clarifier?

- Space Efficiency: Requires up to 80% less space than traditional settling tanks.

- Chemical-Free Operation: Offers a simple design without the need for chemicals.

- Modular and Mobile: Can be easily expanded, installed above or below ground, and is available in containerized versions.

- High Treatment Efficiency: Operates with overflow rates 2 to 4 times higher than traditional clarifiers, allowing greater influent flow rates and more efficient clarification.

4. In which applications can the ClearFox® Lamella Clarifier be used?

The clarifier is suitable for both industrial and municipal applications, including:

- Primary clarification of wastewater

- Wash water recirculation systems (e.g., in fruit & vegetable processing)

- Raw water clarification

- Treatment of effluents in metal finishing, iron and steel plants

- Gravel and sand industry

- Chemical industry

- Municipal water treatment systems

- Wet scrubber and slaking effluents in the power industry

- Thickening processes in the chemical, mining, and mineral industries

5. How is the ClearFox® Lamella Clarifier installed?

The clarifier can be supplied as a complete, easy-to-install container or as a plate pack assembly for installation into concrete or steel tanks. Its modular design allows for flexibility in installation, making it suitable for various site requirements.

6. What maintenance is required for the ClearFox® Lamella Clarifier?

The system is designed for minimal maintenance. Periodic removal of collected sludge from the sludge funnel is necessary, as defined in the control program. Installed alarms inform operators of any issues, ensuring efficient operation.

7. Is the ClearFox® Lamella Clarifier certified?

Yes, the clarifier is CE marked and designed in accordance with DWA design guidelines, ensuring compliance with European quality and safety standards.

8. Can the ClearFox® Lamella Clarifier be integrated with other treatment processes?

Absolutely. The clarifier can be integrated into a wastewater treatment plant as a process technology or used as a stand-alone unit. Its design allows it to be used in conjunction with other process steps, enhancing overall treatment efficiency.

9. What materials are used in the construction of the ClearFox® Lamella Clarifier?

The clarifier is constructed from materials resistant to corrosion, ensuring durability and longevity in various operating conditions.